4 Easy Facts About Motorcycle Parts New Zealand Specialists Described

Table of ContentsThe Facts About Motorcycle Parts New Zealand Specialists UncoveredThe 5-Second Trick For Motorcycle Parts New Zealand SpecialistsThe 7-Minute Rule for Motorcycle Parts New Zealand SpecialistsIndicators on Motorcycle Parts New Zealand Specialists You Need To KnowNot known Factual Statements About Motorcycle Parts New Zealand Specialists Get This Report on Motorcycle Parts New Zealand SpecialistsWhat Does Motorcycle Parts New Zealand Specialists Mean?6 Easy Facts About Motorcycle Parts New Zealand Specialists Described

So, connect to one of our experts today.CNC machining innovation is promptly coming to be the focal point of several manufacturing procedures around the world as a straight result of its many benefits over other methods. Furthermore, the markets that produce bikes have jumped on board with this pattern. One of the most ingenious companies are now creating their engine components and wheels utilizing machining methods originally created for motorcycle components.

On the various other hand, the impacts of industry are the primary emphasis of this write-up. Let's get straight into it. You may be asking yourself why we make use of. It is not hard to fathom the variables that resulted in this result. Since we have your focus allow us clarify the reasoning behind this modern growth in the motorbike manufacturing industry.

Motorcycle Parts New Zealand Specialists Can Be Fun For Anyone

In addition, you have full control over the look of the components, even down to the minute details. Occasionally, motorcyclists might decide to fix up their experience by mounting aftermarket elements or modifying the bike's transformation. Once more, computer mathematical control (CNC) machining is one of the most useful method. Upgrades may be of any type of kind and style you want.

The Greatest Guide To Motorcycle Parts New Zealand Specialists

CNC machining may be used to make virtually all of a motorcycle's steel and plastic components. To proceed, we'll go over a number of machined parts for bikes.

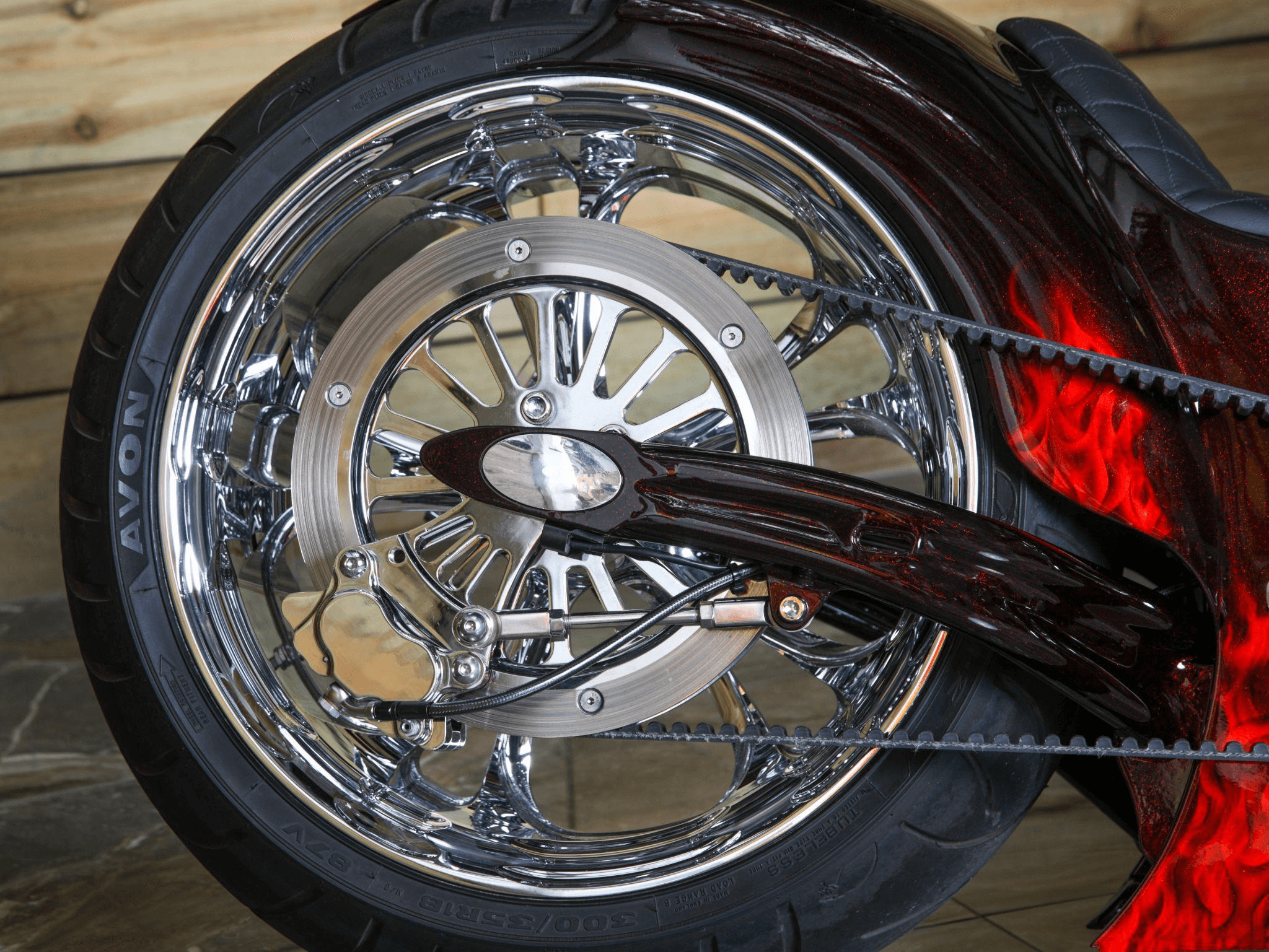

When tailoring the wheels, the disks are where the focus should be. The majority of them are constructed of aluminum. Aluminum alloys are popular for the superior machining abilities that they possess. Milling treatments are utilized to get the desired degree of wheel personalization. An additional element of the motorbike that may be individualized is the tires.

The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Discussing

When it involves a vehicle (or a motorcycle), the most essential part is the engine. A number of individuals allude to it as the "heart" of the vehicle. On the other hand, the camshaft, the cylinder head, and the pistons tend to be elaborate and require designs with a high degree of precision.

Usage only top quality things, nonetheless, because these lights are crucial for the safety of motorcyclists and other motorists or individuals on the road, particularly at night. Motorcycle headlights have three primary components: the bulb, or light resource, the lens, and the housing.

Milling procedures with a flawless finish would certainly result in the lenses having a reflective high quality that resembles that of a mirror. The cover, on the various other hand, is not made up of delicate materials; instead, it is created out of difficult polymers that can be machined right into even more intricate patterns.

Some Known Incorrect Statements About Motorcycle Parts New Zealand Specialists

Motorbike manufacturers typically cast these parts, but just for the production of bespoke parts. Machining on 5 axes in today's globe is the ways by which any type of style form might be understood.

Select Runsom for your customized bike components! We have the capability to fabricate difficult and stylish elements making your motorbike unparalleled.

Right here are a few examples of metals usually used in motorcycle element machining. Light weight aluminum is the primary product utilized by business specializing in creating custom bike components to develop many of these components - Motorcycle Parts New Zealand Specialists.

Zinc refers to one more metal that is really light in weight and has wonderful machining qualities as a result of its high mechanical my review here strength. This material might be formed right into virtually any shape and keeps its measurements well. Even mission-critical elements that need a high level of precision might take advantage of their usage.

4 Simple Techniques For Motorcycle Parts New Zealand Specialists

One more steel that sees hefty use in the manufacturing of CNC-customized parts is magnesium. It is amongst the lightest metals that are now obtainable and has excellent machinability features and toughness compatible with its low weight. One of the drawbacks of magnesium is that its dirt may conveniently ignite.

As a result of its superior machinability and weldability, stainless-steel is an alloy that is especially well-suited for CNC procedures. In addition to this, they have wonderful corrosion resistance and a high aesthetic appeal. Their most typical usage in creating numerous motorbike components is bolts, such as screws and screws. Their reduced sensitivity to oxidation and deterioration makes them optimal for this usage.

The Main Principles Of Motorcycle Parts New Zealand Specialists

It appears that CNC turning and grating are the foundational processes. Different methods exist, such as drilling. Let's check out a number of these machining techniques detailed. The CNC turning strategy is thought about a subtractive manufacturing method. Additionally, it needs maintaining bars of material, frequently plastic or steel, in placement and after that turning a cutting tool to eliminate areas of the product as the material is turned.

These techniques are just as essential and create elements with high precision and consistent high quality. The processes help enhance the overall high quality of the machined bike elements.

Motorcycle Parts New Zealand Specialists - An Overview